Ang mga polyolefin sama sa polypropylene (PP), EPDM-modified PP, Polypropylene talc compounds, Thermoplastic olefins (TPOs), ug thermoplastic elastomers (TPEs) nagkadaghan nga gigamit sa mga aplikasyon sa awto tungod kay kini adunay mga bentaha sa pag-recycle, gaan, ug barato kon itandi sa mga engineering plastics.

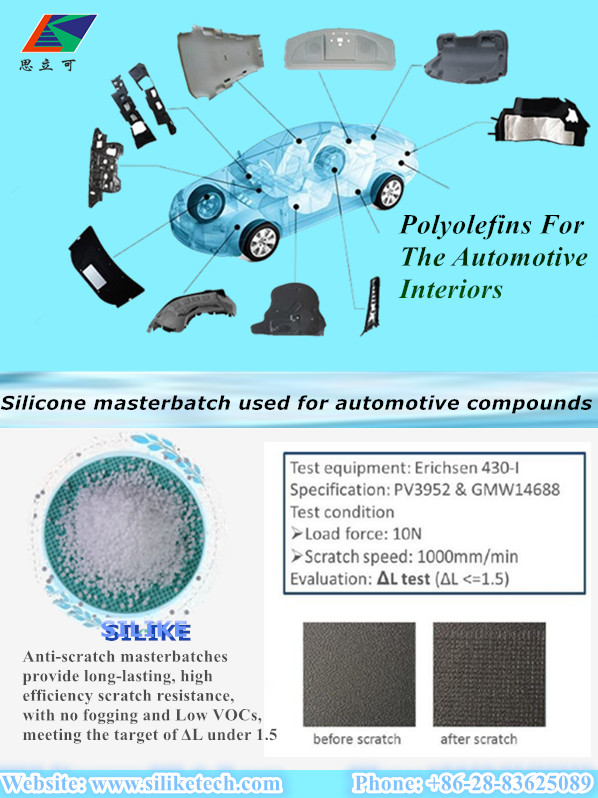

Apan, ang mga polypropylene talc compound, TPO, ug TPE-S dili kaayo makasugakod sa mga gasgas. Kini nga mga Materyales para sa mga aplikasyon sa interior sa awto kinahanglan nga makatuman sa estrikto nga mga kinahanglanon sama sa pagkaproseso, kalig-on, ug pagsukol sa daghang mga substansiya ug pwersa sa tibuok kinabuhi sa serbisyo sa piyesa.

Busa, kon unsaon pagsulbad ang mga problema sa pagkagasgas ug pagkab-ot sa ubos nga panginahanglan sa friction niining mga Polyolefins compound, kinahanglan nga i-adjust sa mga prodyuser ang pormula sa ilang mga produkto aron matubag kini nga mga kinahanglanon.

Mga Masterbatch nga Siliconemahimong mapuslanon sa disenyo sa imong produkto.

Kini makapauswag sa mga kinaiya sa pagproseso sa mga thermoplastic nga materyales ug sa kalidad sa nawong sa nahuman nga mga sangkap para sa mga interior sa awto, tungod kay kini makapauswag sa pag-apod-apod sa mga filler ug pigment ug motapot niini sa polymer matrix. Kini nga mga anchorage group nagsiguro sa usa ka lig-on ug permanente nga set nga walay epekto sa pagbalhin o epekto sa pag-fogging.

SILIKE Pag-focus sa tanang klase samga masterbatch nga silicone.Aditibo nga kontra-gasgasBase sa taas nga molecular weight siloxane, walay migratory, nga mga benepisyo para sa mga compound sa polypropylene sa sakyanan, kini makatabang sa pagpalambo sa dugay nga anti-scratch nga mga kabtangan sa mga interior sa sakyanan, nga nakab-ot ang mga sumbanan sa anti-scratch test nga PV3952 ug GMW 14688. Ubos sa presyur nga 10N, ang ΔL nagkantidad og ubos sa 1.5, walay stickiness, ug ubos nga VOC. Kini angay usab alang sa tanang proseso sa virgin PP sama sa mga appliances sa panimalay, muwebles, ug injection molding application para sa dali nga pagpagawas sa agup-op, anti-scratch, ug uban pa ingon man paghatag og taas nga aesthetics para sa mga instrument panel, consoles, ug door panels…

Oras sa pag-post: Hulyo-11-2022